BMT USA is a member of the MMM Group; one of the world’s leading suppliers of process equipment —including autoclave steam sterilizers—with subsidiaries in over 20 different countries and manufacturing facilities in the USA, Germany and the Czech Republic. Since the beginning in 1954, the group’s sterile products have been placed in Pharmaceutical, Laboratory and Healthcare facilities throughout the world. Special attention is given to quality, reliability, innovation, and efficiency of every unit.

Laboratory Research

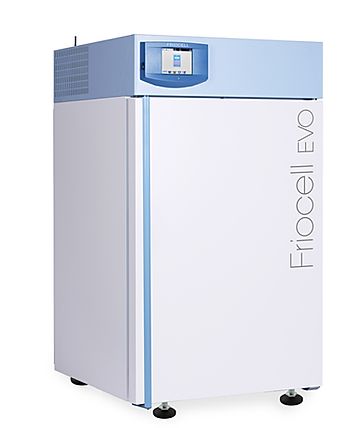

Friocell Temperature Control Incubators

The Friocell allows exact incubation while maintaining precise temperature control.

The unique cooling system ensures that samples do not over dry. Each unit can be equipped with high performance lighting for growth and testing of products. The patented forced air convection ensures even temperature distribution throughout the entire chamber. Ideal for use in food labs, biological laboratories, plant science, cosmetics, materials testing and chemical industries. Elevate sterilization standards with BMT’s unique double chamber design and removable inner chamber.

Dry Heat & Sterilization Ovens - Vacuum Ovens

BMT’s line of ovens includes the ECOCELL, DUROCELL, and VENTICELL lines.

The ECOCELL natural gravity convection produces no noise or vibration while providing exceptional temperature uniformity.

DUROCELL’s chambers are coated with EPOLON. Epolon protects the internal chamber from aggressive and corrosive substances like acids or alkaline liquids.

The Venticell’s patented forced air-flow system moves air both vertically and horizontally through computer engineered precision air ports within the inner chamber.

Incubators: Environmental & Climate Control

The Friocell line features forced air convection and cooling. The high technical standard of the Friocell Incubator allows exact incubation processes while maintaining precise temperature control both for variation and deviation.

In addition to forced air convection and cooling, Climacell incubators also offer humidity control. BMT Incubators’ principle of operation is based on a precise forced air circulation combined with a patented powerful cooling system and a humidifier situated in the chamber. A multiprocessor humidifying and dehumidifying control system together with an optional lighting system ensures perfect homogenous conditions for precise simulation of climatic conditions.

ICH Stability & Photostability

The CLIMACELL series was developed to created exact and reproduce simulation of a wide range of environmental conditions for the testing of pharmaceutical products, plant growth, insect rearing, shelf life testing of food, materials and components. This includes ICH Q1A & Q1B stability, photostability. Secure data storage Warmcomm Software conforming to FDA 21 CFR part 11.

The Climacells’ stainless steel pharmaceutical graded (AISI 304) double-wall chamber design (main & inner chamber) allows for long life expectancy and facilitates the easy cleaning and sterilization of the chamber.

Combine these features with controllable lighting and BMT’s patented air-flow system, humidification and dehumidification creates precise conditions.

BOD & Water Treatment Incubators

The Friocell allows exact incubation while maintaining precise temperature control.

The unique cooling system ensures that samples do not over dry. Each unit can be equipped with high performance lighting for growth and testing of products. The patented forced air convection ensures even temperature distribution throughout the entire chamber. Ideal for use in food labs, biological laboratories, plant science, cosmetics, materials testing and chemical industries.

Microbiological Incubators

The Incucell natural convection is designed for the safe treatment of microbiological cultures. The Incucells’ soft natural gravity air convection greatly reduces particle movement.

Incucell V patented forced / mechanical air movement system provides the advantage of precise temperature distribution in the chamber. The Incucell and Incucell V can be used in biological and microbiological laboratories, quality control tests for pharmacology, cosmetics, veterinary medicine & food and beverage processing are but a few of the applications.

Insect Rearing & Aqua Culture

The advanced technical features of the FRIOCELL® line allows precise control of the heating and cooling process from -20 up to +100°C. The unique cooling system offers an exact and economical simulation of selected natural processes while reducing the drying of samples. Used in the field of bio-technologies, botany, zoology, food technology, cosmetics, chemistry, etc., where they allow extremely short start-up times and regeneration of temperature conditions are required.

The CLIMACELL line of air-conditioned chambers provides all and any conditions for exact and reproducible simulation of various climatic conditions. Thanks to a wide range of adjustable parameters -20°C up to +100°C (-4°F – 212°F ) of temperature and 10–95% of humidity, optional light sources and the opportunity for CO2 regulation, sterilization at 160°C (320°F) and a variety of options and accessories, the new generation of the stability chamber, Climacell EVO becomes an ideal tool for simulation of conditions in many fields and applications. Simple control via the color touch screen controller,

precise parameters and wide options for data output meet the most demanding conditions of the pharmaceutical and laboratory industries.

CO2 Cell Incubators

BMT CO2 Cell incubators are focused on constant and repeatable conditions for cell growth, tissue and other culturing procedures. The Direct Heat system is fan-less, virtually eliminating cross contamination, condensation and consequently vibration. Thanks to the unique 6-sided – 3 circuit direct heated chamber contamination control and condensation on the inner glass door and walls is achieved and maintenance is greatly reduced.

The Drift-free IR sensor provides maximum reliability, precision and quick recovery after door opening.

Freeze Thaw Chambers

The FRIOCELL EVO is the evolution in BMT chambers, designed to create exact and reproducible simulation of environmental conditions including but not limited to microbiology, plant growth, photo stability and stability.

The Friocell’s fuzzy logic enabled microprocessor allows for complete control of incremental temperature increases in chamber temperature for Freeze-Thaw studies. Complete data reporting, evaluation and security is available with Warmcomm 4.0F Software, FDA 21 CFR part 11 conformity.

The EVOs’ all stainless steel (AISI 304) double-wall chamber design (main & inner chamber) allows for long life expectancy and elevates contamination control by facilitating the easy cleaning and sterilization.

Food and Beverage Industry

Stability & Shelf Life Studies

The CLIMACELL series was developed to created exact and reproduce simulation of a wide range of environmental conditions for the testing of pharmaceutical products, plant growth, insect rearing, shelf life testing of food, materials and components. This includes ICH Q1A & Q1B stability, photostability. Secure data storage Warmcomm Software conforming to FDA 21 CFR part 11.

The Climacells’ stainless steel pharmaceutical graded (AISI 304) double-wall chamber design (main & inner chamber) allows for long life expectancy and facilitates the easy cleaning and sterilization of the chamber.

Combine these features with controllable lighting and BMT’s patented air-flow system, humidification and dehumidification creates precise conditions.

Incubators: Temperature Control

The Friocell allows exact incubation while maintaining precise temperature control.

The unique cooling system ensures that samples do not over dry. Each unit can be equipped with high performance lighting for growth and testing of products. The patented forced air convection ensures even temperature distribution throughout the entire chamber. Ideal for use in food labs, biological laboratories, plant science, cosmetics, materials testing and chemical industries. Elevate sterilization standards with BMT’s unique double chamber design and removable inner chamber.

Incubators: Microbiological

The Incucell natural convection is designed for the safe treatment of microbiological cultures. The Incucells’ soft natural gravity air convection greatly reduces particle movement.

Incucell V patented forced / mechanical air movement system provides the advantage of precise temperature distribution in the chamber. The Incucell and Incucell V can be used in biological and microbiological laboratories, quality control tests for pharmacology, cosmetics, veterinary medicine & food and beverage processing are but a few of the applications.

Dry Heat Vacuum Ovens

The Vacucell EVO vacuum direct heat drying oven is ideal for temperature sensitive, easily decomposable or oxidative materials, which must be dried in a very careful process under vacuum. The Vacucell EVO is also used for drying off solvents from chemicals and powders. As well complex components with inaccessible spaces are dried quickly and effectively using the patented Servotherm Heat transfer shelves. The oven is designed to be connected to a central vacuum source or can be equipped with a vacuum pump such as the BMT Vacustation for a complete stand-alone system.

Industrial, Aerospace, Automotive & Electronics

Dry Heat Ovens Vacuum Ovens

The Vacucell EVO vacuum direct heat drying oven is ideal for temperature sensitive, easily decomposable or oxidative materials, which must be dried in a very careful process under vacuum. The Vacucell EVO is also used for drying off solvents from chemicals and powders. As well complex components with inaccessible spaces are dried quickly and effectively using the patented Servotherm Heat transfer shelves. The oven is designed to be connected to a central vacuum source or can be equipped with a vacuum pump such as the BMT Vacustation for a complete stand-alone system.

Temperature Control Chambers

The FRIOCELL EVO is the evolution in BMT chambers, designed to create exact and reproducible simulation of environmental conditions including but not limited to microbiology, plant growth, photo stability and stability.

The Friocell’s fuzzy logic enabled microprocessor allows for complete control of incremental temperature increases in chamber temperature for Freeze-Thaw studies. Complete data reporting, evaluation and security is available with Warmcomm 4.0F Software, FDA 21 CFR part 11 conformity.

The EVOs’ all stainless steel (AISI 304) double-wall chamber design (main & inner chamber) allows for long life expectancy and elevates contamination control by facilitating the easy cleaning and sterilization.

Freeze Thaw Chambers

The FRIOCELL EVO is the evolution in BMT chambers, designed to create exact and reproducible simulation of environmental conditions including but not limited to microbiology, plant growth, photo stability and stability.

The Friocell’s fuzzy logic enabled microprocessor allows for complete control of incremental temperature increases in chamber temperature for Freeze-Thaw studies. Complete data reporting, evaluation and security is available with Warmcomm 4.0F Software, FDA 21 CFR part 11 conformity.

The EVOs’ all stainless steel (AISI 304) double-wall chamber design (main & inner chamber) allows for long life expectancy and elevates contamination control by facilitating the easy cleaning and sterilization.

Environmental Chambers: Temperature Control & Humidity

The Friocell line features forced air convection and cooling. The high technical standard of the Friocell Incubator allows exact incubation processes while maintaining precise temperature control both for variation and deviation.

In addition to forced air convection and cooling, Climacell incubators also offer humidity control. BMT Incubators’ principle of operation is based on a precise forced air circulation combined with a patented powerful cooling system and a humidifier situated in the chamber. A multiprocessor humidifying and dehumidifying control system together with an optional lighting system ensures perfect homogenous conditions for precise simulation of climatic conditions.

Agricultural Science & Technology Plant Growth & Germination Chambers

Temperature Control, Humidity & Lighting Climacell Climacell EVO

The CLIMACELL series was developed to created exact and reproduce simulation of a wide range of environmental conditions for the testing of pharmaceutical products, plant growth, insect rearing, shelf life testing of food, materials and components. This includes ICH Q1A & Q1B stability, photostability. Secure data storage Warmcomm Software conforming to FDA 21 CFR part 11.

The Climacells’ stainless steel pharmaceutical graded (AISI 304) double-wall chamber design (main & inner chamber) allows for long life expectancy and facilitates the easy cleaning and sterilization of the chamber.

Combine these features with controllable lighting and BMT’s patented air-flow system, humidification and dehumidification creates precise conditions.

Temperature Control with Lighting Friocell Friocell EVO

The high technical standard of the Friocell Incubator

allows exact incubation processes while maintaining

precise temperature control both for variation and

deviation. The units have very short recovery times and together with fuzzy logic control ensure there is no temperature overshoot during heating. The unique cooling system ensures that samples are not dried while cooling. The units can be equipped with high-performance lighting for both plant growth and testing of products. Ideal for use in biological laboratories, botany, cosmetics, food processing, and chemical industries.

Cannabis

Your Canadian source for Distek sales and service since 1993