TopAir Systems is a manufacturer and provider of superior clean air and containment solutions. TopAir’s clean air solutions are used in laboratories and manufacturing facilities within chemical/biological plants, universities, research & development facilities and hospitals, as well as in the electronics, semiconductor and pharmaceutical industries.

At TopAir Systems customer satisfaction comes first: The company exercises a flexible approach, customizing products in accordance with customer requests regarding dimensions, technical specifications and accessories. Moreover, TopAir Systems offers a variety of products and models to accommodate and cover customer needs. Finally, the company develops cost-effective solutions of the highest quality, to ensure customer satisfaction.

Product safety is a top priority: The most stringent guidelines are implemented to ensure the well-being of lab and manufacturing personnel, and the products comply with the relevant international certifications.

Ductless Fume Hoods

WHAT’S A DUCTLESS FUME HOOD?

A ductless fume hood is contained ventilation equipment or working space that filters out chemical airborne materials and recycles them back to the working environment as breathable air. It uses activated carbon filters to clean the fumes. Ductless fume hoods usually have a frontal airflow to get the air out at a controlled rate to prevent harmful gases from going out of the workstation.

HOW DOES IT WORK?

There are two filters in a ductless fume hood – the pre-filter and the main filter. Both of them work to remove the contaminants in the fumes. It starts with the ambient air going into the ventilation hood with the gases or vapours produced during the laboratory work. The air in the hood goes through the pre-filter, where some of the impurities are sifted.

Once it has gone through the pre-filter, it goes through the main filters, where other particulates are thoroughly removed. Then, the air goes out from the main filter to the workstation as breathable air.

COMMON APPLICATIONS

Ductless fume hoods are used in various fields. Some of the most common applications are the following:

- Life Sciences

- Forensics, Fingerprinting and DNA

- Educational Purposes

- Clinics and Hospitals

- Dental Laboratory

- Cleanrooms

- 3D Printing

- Archaeology

- Glass Manufacturing

- Mycology

- Soldering

- Pharmaceutical

- Art Restoration

- Production of Glues, Paints, and Solvents

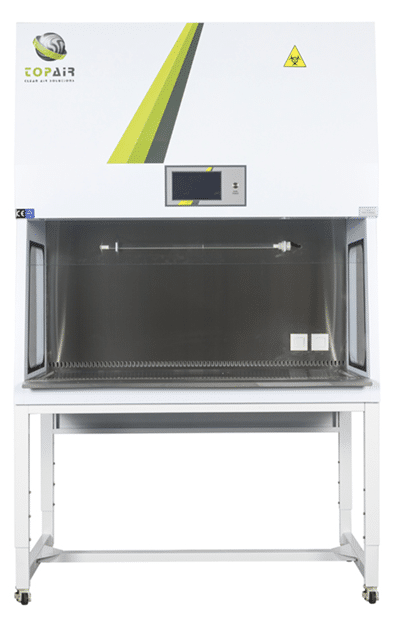

Biosafety Cabinets Class II A2

TopAir’s Class II A2 Biological Safety Cabinet protects lab staff, the environment and sensitive work processes in which biological agents are applied.

The cabinet offers a high level of contamination protection, based on two advanced ULPA filters operating at a typical efficiency of @99.9995% @ 0.1 um with an airflow pattern of 70% downflow and 30% exhaust.

The cabinet is made of robust, easily-cleaned anti-corrosive polypropylene with high resistance to acids and chemicals, which is optimal for clean rooms.

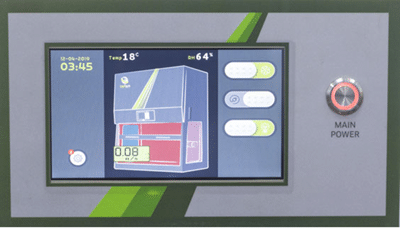

The cabinet is equipped with a smart, safe and elegant touch-screen control system that protects the operator and provides alerts for periodic maintenance actions and devices’ replacement.

All components have low energy consumption, LED lighting and an EC fan motor.

The BO-120-PP model is CE certified, and certified for EN 12469. Other models are CE certified, and comply with EN 12469.

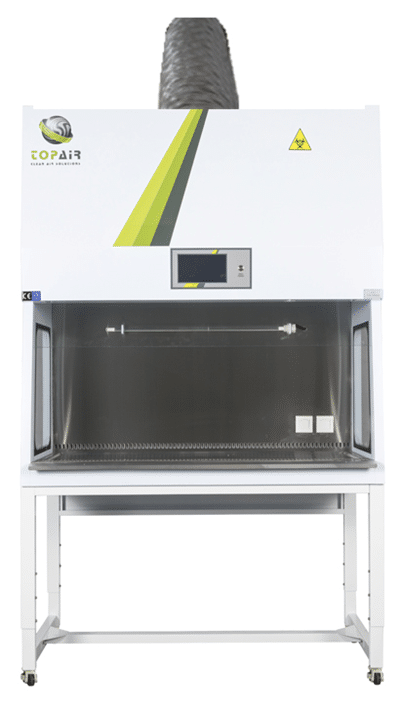

Biosafety Cabinets Class ll B2

TopAir’s Class II B2 Biological Safety cabinet, featuring 100% exhaust, protects lab staff, the environment and sensitive work processes in which biological agents are applied.

The cabinet offers a high level of contamination protection, based on two advanced ULPA H15 filters operating at an efficiency of @99.9995% @ 0.1 um.

The cabinet is made of robust, easily-cleaned anti-corrosive polypropylene with high resistance to acids and chemicals, which is optimal for clean rooms.

The cabinet is equipped with a smart, safe and elegant touch-screen control system that protects the operator and provides alerts for periodic maintenance actions and devices’ replacement.

There is a dual separate airflow system with inflow and downflow hot wire sensors, with each of them delivering air velocity value and alarms.

All components have low energy consumption, LED lighting and an EC fan motor.

The BO-120-PP-B model is CE certified, and complies with EN 12469.

PCR Cabinets

TopAir’s Polypropylene PCR-UV cabinets offer complete protection from contamination.

Made of high-quality non-corrosive polypropylene, the cabinets feature a high level of chemical resistance. Polypropylene increases the product’s tensile strength and improves its thermal characteristics.

The cabinets are used in the genomics, proteomics, molecular biology and forensic sciences industries.

They feature an ergonomic design and premium materials.

The PCR Hood complies with Test Standard USA Federal Standard 209E / CE /

ISO 1- 144641.

TopAir’s Polypropylene PCR-HEPA cabinets offer a quality filtering system which provides complete protection from contamination.

Made of high-quality non-corrosive polypropylene, the cabinets feature a high level of chemical resistance. Polypropylene increases the product’s tensile strength and improves its thermal characteristics.

The cabinets are used in the genomics, proteomics, molecular biology and forensic sciences industries.

They feature an ergonomic design and premium materials, including a cutting-edge motor fan ensuring long-term durability and low noise.

The cabinet complies with Test Standard: USA Federal Standard 209E / ISO 14644-1 and has CE certification.

levels.

The PCR Hood complies with Test Standard USA Federal Standard 209E / CE /

ISO 1- 144641.

Laminar Clean Bench

TopAir’s advanced Forensic Evidence Drying Hood protects wet or damp evidence from detrimental factors such as potential cross contamination and airborne pathogens.

The hood also creates an effective shield for staff, preventing the operators from being exposed to harmful blood-borne pathogens and harmful bacteria or viruses.

The unit’s UV light performs additional disinfection of the Hood’s interior between sessions. This prevents cross contamination and ensures the integrity of samples for the purpose of DNA testing.

The unit is designed to clean the incoming air streams through pre-filtration and then filter the Hood exhaust air using HEPA filtration.

TopAir can customize the ductless evidence drying Hoods to meet customer requirements.

Forensic Evidence Drying Hood

TopAir’s advanced Forensic Evidence Drying Hood protects wet or damp evidence from detrimental factors such as potential cross contamination and airborne pathogens.

The hood also creates an effective shield for staff, preventing the operators from being exposed to harmful blood-borne pathogens and harmful bacteria or viruses.

The unit’s UV light performs additional disinfection of the Hood’s interior between sessions. This prevents cross contamination and ensures the integrity of samples for the purpose of DNA testing.

The unit is designed to clean the incoming air streams through pre-filtration and then filter the Hood exhaust air using HEPA filtration.

TopAir can customize the ductless evidence drying Hoods to meet customer requirements.

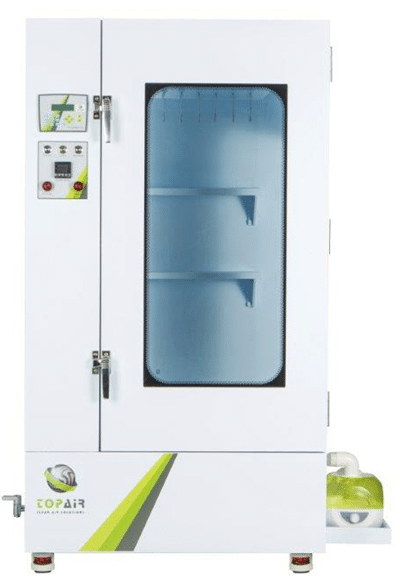

Cyanoacrylate Fuming Chambers

TopAir’s Cyanoacrylate Fuming Chambers are used to develop latent prints from non-porous surfaces in a safe, controlled environment.

Cyanoacrylate is placed inside the chamber while evidence is easily positioned using the adjustable hanging rods. Starting the cycle triggers the automated system to control the hotplate, humidity, door lock, internal circulation fan and purge cycle.

Its recirculatory design enables the system to operate and setup with no ducting required.

The cyanoacrylate vapors are filtered by a carbon filter. This ensures that no dangerous substances are exhausted in to the atmosphere surrounding the laboratory. Its ductless construction also allows the unit to be easily moved and transported.

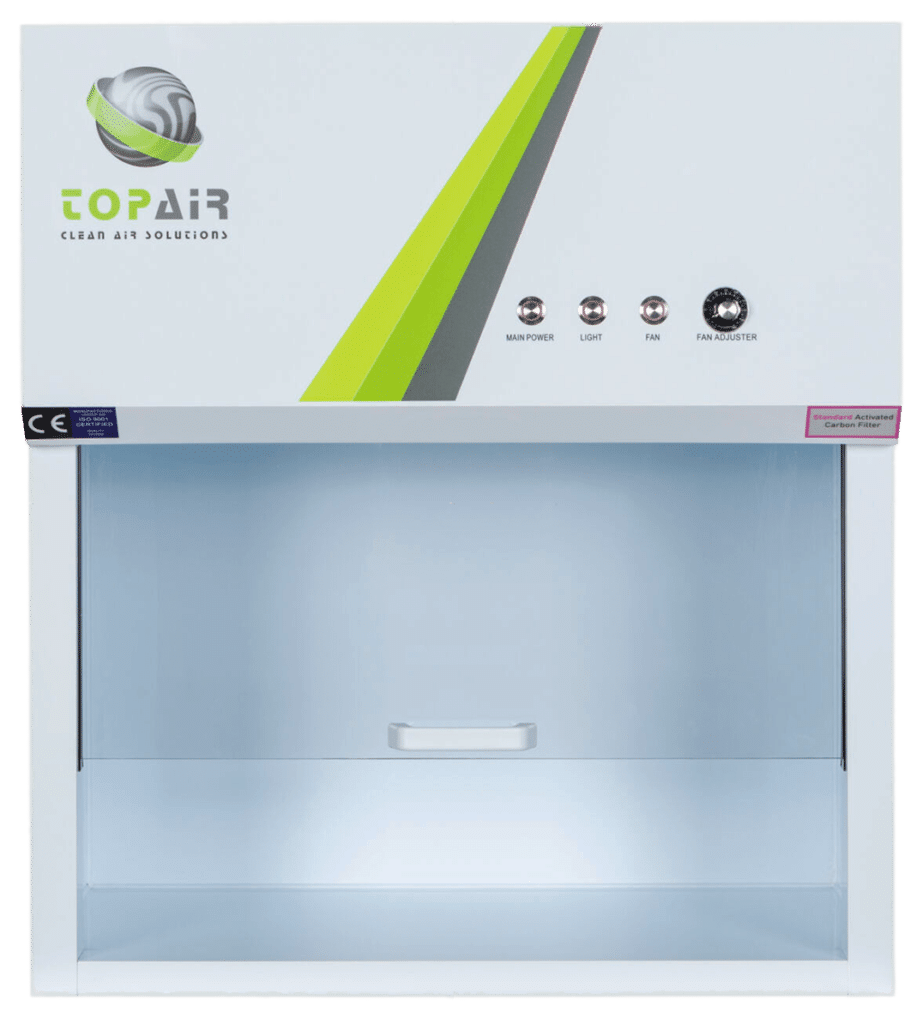

Super Ecoline Ductless Fume Hood

Topair’s Super Ecoline Ductless Fume Hood provides a safe work environment for lab staff working with acids and harsh chemicals.

This is the most cost-effective model of TopAir’s ductless fume hoods, with an innovative and integral polypropylene worktop, a front sash, an environmental friendly EC fan and LED light.

TopAir’s Ecoline Ductless Fume Hoods can be customized to the requirements of each client.

Ecoline Biosafety Cabinet

TopAir’s Ecoline Biosafety Cabinet protects lab staff, the environment and sensitive work processes in which biological agents are applied.

A compact, especially cost-effective benchtop unit, the cabinet offers a high level of contamination protection, based on two advanced ULPA H15 filters operating at an efficiency of @99.9995% @ 0.1 um, with an airflow pattern of 70% downflow and 30% exhaust.

The cabinet is made of robust, easily-cleaned anti-corrosive polypropylene with high resistance to acids and chemicals, which is optimal for clean rooms.

The cabinet is equipped with a smart, safe and elegant touch-screen control system that protects the operator and provides alerts for low airflow levels.

All components have low energy consumption, LED lighting and fan.

The cabinet is CE certified.

Fume Cupboards

Topair’s Fume Hoods protect laboratory staff from noxious fumes when working with acids, dangerous gas, organic solvents, etc. Harmful and unpleasant chemical fumes are removed from the controlled environment to facilitate a safe and pleasant work environment.

The fume hood channels chemical vapors out of the building using an external fan installed on the roof or on an external wall.

The hood structure is made of epoxy-covered metal, while the internal structure is made of HPL 6mm.

The hoods are EN-14175 / CE / ASHRAE 110-1995 certified.

TopAir Fume Cupboards and Fume Hoods are manufactured in metal and polypropylene. Active and Laminar Flow models are available, as well as washdown models. Units specially designed for use with perchloric and hydrofluoric acid are also available.

VAV System - Auto Air Velocity Control System

TopAir’s advanced VAV system measures the product’s air velocity using a high quality sensor, and adjusts the air velocity speed to the relevant standard. The system enables maximal energy savings, by flexibly adjusting the fan speed (high/low) to changing needs. Further savings are enabled in the area of air conditioning, as the airflow from the room is reduced when the fan operates at a lower speed. This also reduces the fume cupboard’s noise level.

The system keeps the user updated as to the airflow speed at all times and provides alerts on deviations from the required speed to prevent hazardous situations.

TopAir’s VAV System introduces an entirely new concept for intelligent operation of fume cabinets. As a complete solution, all its components are already integrated, configured and programmed – a true plug-and-play system. Rather than separately purchasing a control system, touch screen and frequency inverter, and employing technicians to integrate and install each component, the VAV System offers the customer a full – and much more cost-effective – solution.

The VAV System can be used to renovate an existing fume cabinet, or can be installed in a new fume cabinet. In both cases, it upgrades the fume cabinet into a high-end intelligent system.

The VAV System comprises:

A touch screen including visual and audio indicators for alerts, as well as a mute button.

A unit including sensors and power supply for the screen.

VFD (Variable Frequency Drive) which controls the frequency and voltage supplied to the motor.

Made in the USA, the VAV System is a highly reliable and user-friendly system for setup and use.

The system can be installed in research labs, healthcare facilities, life science companies, universities, and more.

Your Canadian source for Distek sales and service since 1993